INFORMATION

The Strength and Versatility of Woven Cord Strapping

Introduction

Woven cord strapping, often referred to as webbing, is a versatile and strong material used in various industries. Its strength and adaptability make it an ideal choice for various applications, including securing loads, bundling materials, and even as a safety measure in harnesses. In this article, we will explore the properties of woven cord strapping that make it a preferred choice for many industries and applications.

History of Woven Cord Strapping

The use of woven cord strapping dates back to ancient civilizations, with the earliest examples found in Egyptian tombs. Over time, the materials and techniques used to create woven cord strapping have evolved. Today, woven cord strapping is made from synthetic materials such as polypropylene, nylon, and polyester, which offer improved strength and durability compared to their natural fiber counterparts.

Properties of Woven Cord Strapping

1. Strength: Woven cord strapping is known for its exceptional strength, which is a result of its construction. The material is made up of multiple strands of yarn or filament, which are interwoven to create a strong and durable cord. The strength of woven cord strapping is measured in kilograms per square millimeter, with higher values indicating a stronger material.

2. Flexibility: Woven cord strapping is highly flexible, allowing it to be easily bent and shaped around various objects. This flexibility makes it an ideal choice for securing and bundling materials, as it can conform to the shape of the object being secured.

3. Abrasion Resistance: Woven cord strapping is resistant to abrasion, meaning it can withstand repeated friction without wearing down or fraying. This property makes it ideal for applications where the strapping is subject to constant movement or friction, such as in Straps or seat belts.

4. Lightweight: Woven cord strapping is relatively lightweight, which makes it easy to handle and transport. This is particularly useful in applications where weight is a concern, such as in the aerospace industry or for load securing in transportation.

5.Weather Resistance:Woven cord strapping is resistant to UV rays, mildew, and rot, making it suitable for outdoor use. This property makes it a popular choice for applications in the marine, agricultural, and construction industries.

Applications of Woven Cord Strapping

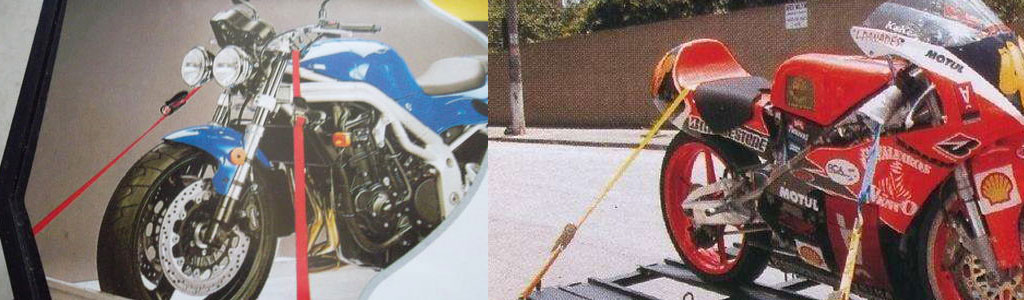

1. Load Securing: Woven cord strapping is commonly used to secure loads in transportation, such as in trucks, trains, and ships. It is also used to secure goods during storage and transit.

2. Bundling: Woven cord strapping is used to bundle materials together, such as in the agricultural industry, where it is used to bundle hay and straw. It is also used to bundle cables, wires, and other materials in the electrical and telecommunications industries.

3. Safety Equipment: Woven cord strapping is used in the manufacturing of safety equipment, such as harnesses and lifting slings. Its strength and flexibility make it an ideal choice for these applications, as it can withstand the stresses and strains placed on it while ensuring the safety of the user.

4. Furniture and Upholstery: Woven cord strapping is used in the furniture and upholstery industries, where it is used to secure cushions, mattresses, and other upholstered items.

Conclusion

Woven cord strapping is a versatile and strong material that has numerous applications across various industries. Its strength, flexibility, abrasion resistance, lightweight, and weather resistance make it an ideal choice for securing loads, bundling materials, and even as a safety measure in harnesses. As technology continues to advance, it is likely that woven cord strapping will continue to be a popular choice for many industries and applications.

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved