INFORMATION

The Evolution and Impact of Wire Buckles in Industrial Packaging

I. Introduction to Wire Buckles

Wire buckles are essential components in the field of industrial packaging, serving as key elements in securing and fastening straps for the transportation of goods. These small but mighty devices play a critical role in ensuring the safety and stability of cargo during transit, making them indispensable in various industries such as logistics, shipping, and manufacturing. This article delves into the evolution and impact of wire buckles, exploring their history, functionality, and future trends in industrial packaging.

II. Historical Overview of Wire Buckles

The concept of using wire buckles for strapping dates back to ancient times when materials such as ropes and cords were utilized to bind and secure goods for transport. Over the years, advancements in metallurgy and manufacturing techniques led to the development of more sophisticated wire buckles, offering increased strength and reliability in securing loads. The industrial revolution further propelled the evolution of wire buckles, with the demand for efficient and durable strapping solutions driving innovation in their design and functionality.

III. Functionality and Benefits of Wire Buckles

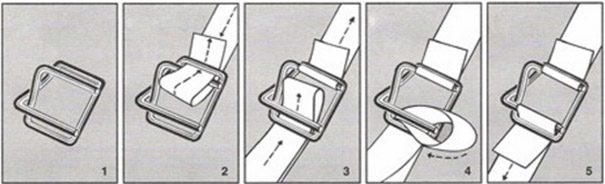

Wire buckles are typically made of high-strength steel or other durable materials, providing a secure anchor point for straps to be threaded through and tightened around cargo. Their simple yet effective design allows for quick and easy installation, making them a popular choice for securing a wide range of loads, from lightweight packages to heavy machinery. The benefits of wire buckles include their ability to withstand high tension forces, resistance to corrosion and wear, and compatibility with various strapping materials such as polyester and polypropylene. Additionally, wire buckles offer cost-effective solutions for bundling and securing goods, contributing to overall efficiency in the packaging and transportation process.

IV. Evolution of Wire Buckle Designs

As technology continues to advance, the design and construction of wire buckles have undergone significant improvements to meet the evolving needs of the industry. Modern wire buckles now feature enhanced ergonomics, with ergonomic handles and grips for easier handling and application. Furthermore, innovations in manufacturing techniques have led to the development of lightweight yet durable wire buckles that offer increased strength-to-weight ratios, allowing for greater load capacity and efficiency in strapping operations. Additionally, the integration of advanced coatings and finishes has improved the durability and longevity of wire buckles, ensuring reliable performance in various environmental conditions.

V. Future Trends in Wire Buckle Technology

Looking ahead, the future of wire buckles in industrial packaging is poised for further innovation and development. Advancements in materials science and engineering are expected to lead to the creation of wire buckles with superior strength and durability, capable of withstanding even higher tension forces and heavier loads. The integration of smart technologies, such as RFID tags and sensors, into wire buckle designs may enable real-time monitoring of strap tension and cargo status, enhancing safety and security during transport. Additionally, environmentally-friendly materials and sustainable manufacturing practices are likely to drive the adoption of eco-friendly wire buckles, aligning with the industry's growing focus on sustainability and green packaging solutions.

VI. Best Practices for Using Wire Buckles

When utilizing wire buckles for industrial packaging, it is essential to follow best practices to ensure optimal performance and safety. Selecting the appropriate size and type of wire buckle based on the application and load requirements is crucial for achieving secure and reliable strapping. Proper tensioning of the straps and ensuring even distribution of the load across the wire buckle can help prevent slippage and shifting during transit. Regular inspection and maintenance of wire buckles, including checking for signs of wear or damage, are recommended to uphold their functionality and longevity. Storing wire buckles in a clean, dry environment away from harsh chemicals or extreme temperatures can help preserve their integrity and performance over time.

VII. Conclusion

In conclusion, wire buckles play a vital role in industrial packaging, offering a reliable and efficient solution for securing goods during transport. The evolution of wire buckle technology has led to the development of robust and versatile devices that contribute to the safety, stability, and cost-effectiveness of packaging operations. As the industry continues to advance, the future of wire buckles holds exciting possibilities for further innovation and enhancement in design, materials, and functionality. By embracing these trends and best practices, businesses can harness the full potential of wire buckles to optimize their packaging processes and ensure the safe and secure delivery of goods to their destinations.

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved