INFORMATION

The Evolution and Applications of Hot Melt Strapping in Modern Industries

Introduction:

In the realm of modern packaging and logistics, efficiency, reliability, and sustainability stand as paramount virtues. Among the various innovations that have emerged to meet these demands, hot melt strapping has steadily risen to prominence. This article delves into the evolution, applications, and benefits of hot melt strapping, elucidating its pivotal role in modern industries.

Evolution of Hot Melt Strapping:

Hot melt strapping, also known as hot melt banding, has undergone significant evolution since its inception. Initially developed as an alternative to traditional strapping methods such as metal bands and polyester straps, hot melt strapping emerged as a versatile solution offering superior strength, flexibility, and cost-effectiveness.

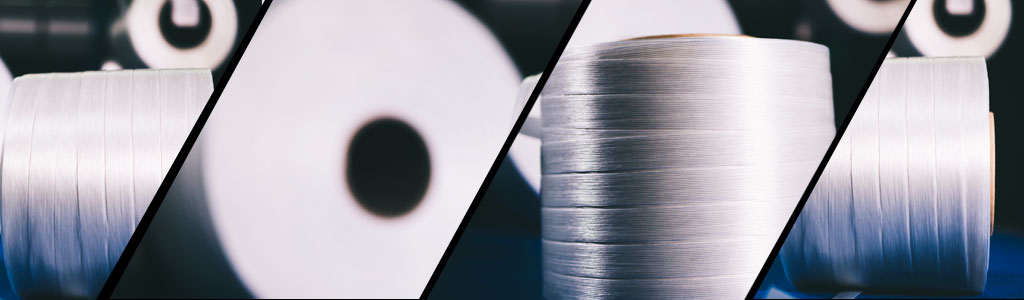

The technology behind hot melt strapping involves the use of thermoplastic materials, typically polypropylene or polyester, which are heated to high temperatures and then molded into straps. These straps are characterized by their ability to form strong and secure bonds when cooled, making them ideal for various packaging and bundling applications.

Applications Across Industries:

Hot melt strapping finds extensive applications across a myriad of industries, owing to its versatility and reliability. In the logistics sector, hot melt strapping serves as a primary means of securing packages, pallets, and shipments during transit, safeguarding against damage and ensuring stability.

Moreover, hot melt strapping has gained traction in industries such as manufacturing, construction, and agriculture, where it is utilized for bundling goods, securing loads, and reinforcing structures. Its ability to withstand varying environmental conditions, including extreme temperatures and moisture, makes it indispensable in diverse operational settings.

Benefits of Hot Melt Strapping:

The adoption of hot melt strapping offers a plethora of benefits for businesses and industries alike. Firstly, its lightweight nature translates to reduced shipping costs and enhanced maneuverability, contributing to overall operational efficiency.

Additionally, hot melt strapping boasts exceptional tensile strength and resistance to stretching, ensuring that bundled items remain secure and intact throughout the shipping process. This not only minimizes the risk of product damage but also enhances customer satisfaction by delivering goods in pristine condition.

Furthermore, hot melt strapping is highly customizable, allowing for tailored solutions to meet specific packaging requirements. Whether bundling heavy-duty machinery or delicate electronics, hot melt strapping offers versatility and adaptability, ensuring optimal protection for diverse goods.

Environmental Considerations:

In an era increasingly defined by sustainability concerns, hot melt strapping emerges as a environmentally-friendly alternative to traditional strapping materials. Unlike metal bands or nylon straps, hot melt strapping is fully recyclable, reducing waste and minimizing ecological impact.

Moreover, the manufacturing process of hot melt strapping consumes less energy and generates fewer emissions compared to conventional strapping materials, aligning with broader efforts towards eco-conscious practices. By opting for hot melt strapping, businesses can not only enhance operational efficiency but also contribute to environmental stewardship.

Conclusion:

In conclusion, hot melt strapping stands as a testament to innovation and efficiency in modern packaging and logistics. From its humble beginnings as a substitute for traditional strapping materials to its widespread adoption across industries, hot melt strapping has revolutionized the way goods are packaged, shipped, and secured.

With its exceptional strength, versatility, and sustainability, hot melt strapping continues to play a pivotal role in enhancing operational efficiency, reducing costs, and minimizing environmental impact. As industries evolve and embrace new technologies, hot melt strapping remains a steadfast ally in the pursuit of excellence and sustainability in packaging and logistics.

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved