INFORMATION

Enhancing Efficiency and Safety: The Importance of Bale Press Strapping in Industrial Packaging

In the bustling world of industrial manufacturing and logistics, efficiency and safety are paramount concerns. One crucial aspect of this landscape is the process of bale press strapping, a fundamental step in securing materials for transportation and storage. From cardboard to plastic to metal, bale press strapping plays a vital role in bundling these materials securely, ensuring they reach their destinations intact. In this article, we will delve into the significance of bale press strapping, its various applications, and the benefits it brings to the industrial sector.

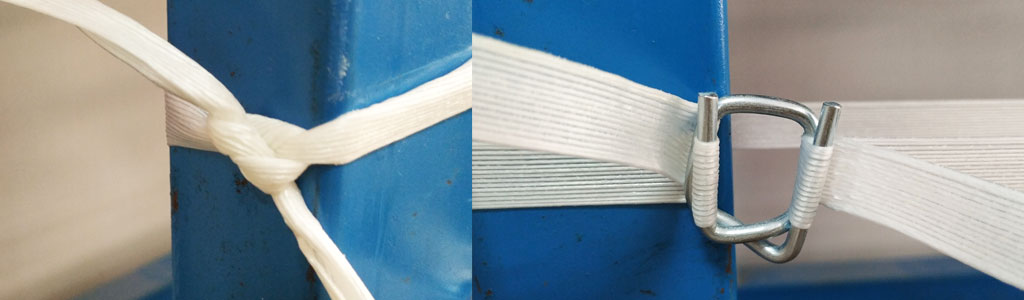

**Understanding Bale Press Strapping**

Bale press strapping, also known as banding or bundling, involves the use of sturdy straps to tightly bind together materials such as paper, cardboard, plastic, or metal. The process typically takes place within a baling or compacting machine, where the materials are compressed into compact bales before being strapped.

**Applications Across Industries**

The versatility of bale press strapping makes it indispensable across a wide range of industries. In the recycling sector, for example, bale press strapping is used to compact and secure materials like cardboard, paper, and plastics for efficient transportation to recycling facilities. Similarly, in the agricultural sector, bales of hay or straw are strapped to facilitate storage and transportation. Even in manufacturing, bale press strapping is utilized to bundle metal scraps or other materials for recycling or disposal.

**Ensuring Safety in Transportation and Storage**

One of the primary objectives of bale press strapping is to enhance safety during transportation and storage. By securely binding materials into compact bales, the risk of shifting or spillage during transit is significantly reduced. This not only prevents damage to the materials but also minimizes the potential for accidents or injuries caused by loose or unstable loads. Additionally, bale press strapping helps to optimize warehouse space by allowing for neat and organized stacking of bales, maximizing storage capacity.

**Improving Operational Efficiency**

In addition to enhancing safety, bale press strapping also contributes to operational efficiency in industrial settings. By streamlining the bundling process, it reduces the time and labor required to prepare materials for shipment or storage. This, in turn, translates to cost savings and increased productivity for businesses. Furthermore, the use of high-quality strapping materials ensures that bales remain securely bound throughout the entire supply chain, reducing the need for rework or replacements.

**Environmental Benefits**

Beyond its immediate operational advantages, bale press strapping also offers environmental benefits. By facilitating the efficient recycling and disposal of materials, it supports sustainability initiatives within the industrial sector. Compact bales of recyclable materials take up less space in landfills or recycling facilities, reducing the overall environmental footprint of waste management processes. Additionally, the use of recycled or biodegradable strapping materials further minimizes environmental impact.

**Innovation and Advancements**

As technology continues to evolve, so too does the field of bale press strapping. Modern baling machines are equipped with advanced features such as automated strapping systems, precision control mechanisms, and enhanced safety protocols. These innovations not only improve the efficiency and effectiveness of the strapping process but also ensure compliance with industry standards and regulations.

**Conclusion**

In conclusion, bale press strapping is a critical component of industrial packaging, offering benefits that extend far beyond simple bundling. From enhancing safety and efficiency to supporting environmental sustainability, its importance cannot be overstated. As industries continue to evolve and adapt to changing demands, bale press strapping will remain an essential tool for securing materials and optimizing operations.

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved