SOLUTION

The Art of Composite Strapping

Composite Strapping丨Polyester Strapping丨Composite Corded Strap Factory

Introduction

Composite strapping is an innovative and versatile solution for a wide range of applications in various industries. It is a type of strapping material

that combines the strength and durability of metal with the lightweight and corrosion-resistance properties of plastic. This article will explore the

unique features of composite strapping, its benefits, and its wide range of applications.

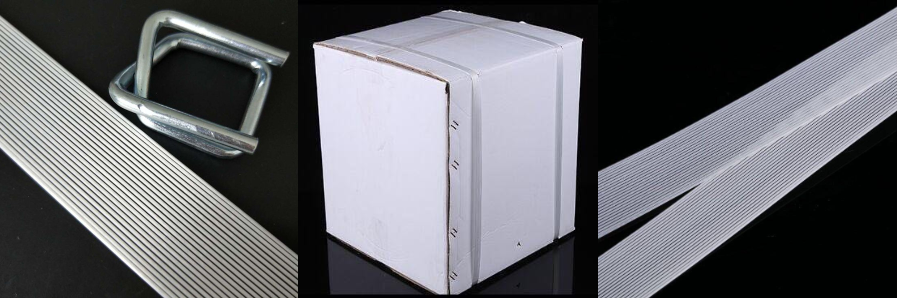

Composite strapping is made from a combination of polyester and steel materials. The polyester resin is extruded onto a steel core, creating a strong

and durable bond between the two materials. This unique construction process allows the composite strapping to possess the best qualities of both

materials, providing exceptional strength, flexibility, and corrosion resistance.

Benefits of Composite Strapping

1. Strength: Composite strapping offers a high tensile strength, making it an ideal choice for applications that require a secure and strong binding.

2. Lightweight: The composite material is much lighter than traditional metal strapping, making it easier to handle and transport.

3. Corrosion Resistance: The polyester coating provides excellent corrosion resistance, which is particularly useful in environments where metal strapping

may be exposed to moisture or chemicals.

4. Flexibility: Composite strapping is highly flexible, allowing it to be used in a wide range of applications without compromising its strength.

5. Cost-Effective: The combination of polyester and steel materials makes composite strapping a cost-effective solution compared to other strapping materials.

Applications of Composite Strapping

The unique properties of composite strapping have made it an ideal choice for a wide range of applications, including:

1. Industrial Packaging: Composite strapping is often used to secure pallets and other large shipments, ensuring that they remain secure during transportation.

2. Agriculture: Composite strapping is used to band hay bales and other agricultural products, providing a secure and durable binding that can withstand harsh

weather conditions.

3. Construction: Composite strapping is used in the construction industry to secure building materials, such as steel beams and concrete blocks, during transportation

and installation.

4. Marine Industry: Composite strapping is used to secure cargo on ships and boats, providing a strong and durable binding that can withstand harsh marine

environments.

5. Recycling: The recycling industry utilizes composite strapping to secure materials during transportation and processing, making it an environmentally

friendly choice.

Conclusion

Composite strapping is a versatile and innovative solution for a wide range of industries, offering the best of both metal and plastic materials.

Its unique combination of strength, flexibility, corrosion resistance, and cost-effectiveness makes it an ideal choice for various applications.

As the demand for stronger and more durable strapping materials continues to grow, composite strapping is poised to play an increasingly

important role in the future of packaging and transportation.

BSTSTRAP

Whatsapp:+86 186 5722 7862

E-mail:claire@bststrap.com

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved