INFORMATION

Composite Strapping: A Safeguard in Heavy-Duty Cargo Transportation

In the realm of heavy-duty cargo transportation, ensuring the safety and integrity of goods during transit is paramount. The challenges posed by large, bulky, and often fragile cargo items necessitate the adoption of innovative and reliable packaging solutions. Among these, Composite Strapping has emerged as a game-changer, providing robust support and unparalleled security during the arduous journey from one destination to another.

Introduction to Composite Strapping

Composite Strapping, as its name suggests, is a type of strapping material that combines multiple materials to create a superior product. Typically, it incorporates high-strength fibers such as polyester or polypropylene with reinforcing agents, resulting in a lightweight yet incredibly durable strapping solution. This unique blend of materials imparts exceptional tensile strength, flexibility, and resistance to abrasion, making Composite Strapping ideally suited for heavy-duty cargo transportation.

Benefits in Heavy-Duty Transportation

1. Increased Tensile Strength

Heavy cargo, whether it's machinery, construction equipment, or other large items, places immense strain on packaging materials. Composite Strapping, with its reinforced fibers, can withstand significantly higher tensile loads than traditional steel strapping or even polyester alone. This enhanced strength ensures that cargo remains securely bound during transport, even over rough roads and through adverse weather conditions.

2. Lightweight and Easy to Handle

Despite its impressive strength, Composite Strapping is significantly lighter than steel alternatives. This lightness makes it easier for logistics personnel to handle and maneuver during the packaging process. Moreover, reduced weight translates into lower fuel consumption and reduced carbon emissions during transportation, aligning with the industry's growing focus on sustainability.

3. Excellent Durability and Resistance

Heavy cargo often traverses long distances, exposing it to a myriad of potential hazards. Composite Strapping is designed to withstand the rigors of transportation, including abrasion, moisture, and temperature fluctuations. Its durable nature ensures that the strapping remains intact, maintaining the integrity of the cargo throughout the journey.

4. Customizable and Versatile

Composite Strapping comes in a variety of widths, thicknesses, and lengths, allowing for customization to suit specific cargo requirements. Whether it's securing a single pallet or bundling multiple items together, Composite Strapping offers the flexibility to adapt to various packaging scenarios. Furthermore, its ability to withstand custom printing enhances visibility and facilitates cargo identification.

Application in Heavy-Duty Transportation

1. Secure Palletization

In heavy-duty transportation, pallets serve as the backbone of cargo handling. Composite Strapping is used extensively to secure pallets, ensuring that they remain intact and stable during transport. The high tensile strength of Composite Strapping prevents pallets from shifting or collapsing, protecting the cargo within.

2. Bundling Large Items

For oversized or irregularly shaped cargo, Composite Strapping provides a reliable means of bundling. By tightly securing multiple items together, Composite Strapping minimizes the risk of movement during transportation, thereby preventing potential damage to the cargo or surrounding structures.

3. Container Loading and Securing

In containerized shipping, Composite Strapping plays a crucial role in ensuring that cargo is properly loaded and secured within the container. Its durability and high strength allow it to withstand the forces experienced during sea voyages, minimizing the risk of cargo shifting or becoming loose.

Case Study: Composite Strapping in Action

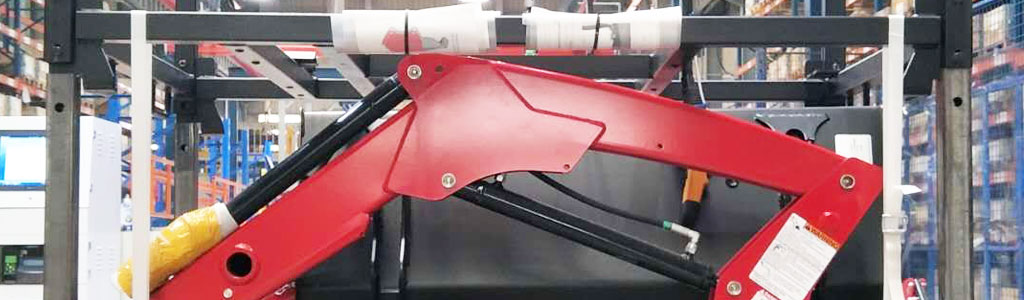

Consider the transportation of a large construction crane from a manufacturing facility to a construction site. The crane, weighing several tons and occupying a significant volume, requires careful packaging and securing to ensure its safe arrival. Composite Strapping is used to bundle the crane's various components together, while also securing the entire assembly to the shipping pallets or containers. Its high strength ensures that the crane remains intact even when subjected to rough handling or inclement weather conditions.

Conclusion

In conclusion, Composite Strapping has revolutionized heavy-duty cargo transportation by providing a robust, lightweight, and versatile packaging solution. Its exceptional tensile strength, durability, and adaptability make it an invaluable tool for logistics professionals tasked with ensuring the safe and efficient transport of large, bulky, and often fragile cargo. As the industry continues to evolve, Composite Strapping will undoubtedly play an increasingly important role in safeguarding the integrity of goods during their journey from one destination to another.

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved